Ian Mitchell, August 2023

3D printing is a great hobby for people of all ages and experience. It can also be a lucrative business if you want it to be and have the ability and funds to finance it. However, both of these paths lead to financial outlay and not just in terms of the printer itself. So, in this article, I’m going to take a look at 3d printing materials cost.

There are two main methods of 3D printing for home users at present. FDM (Fused Deposition Modelling) and SLA (Stereolithograpy) more commonly known as resin printing. For the purposes of this article I’m going to focus on FDM printing but may well revisit this with an SLA version in the future.

So, how can we calculate what 3D printing materials cost? Let’s take a look at the first part which is the cost of the filament.

Filament Costs

Average prices

This is the material cost that will become a regular part of your 3D printing life and something that can vary greatly in price. As you’ll probably be aware, and as I’ve mentioned many times before, the most commonly used filament is PLA (Polylactic Acid). This is an easy to work with and pretty versatile filament so is the best choice for most 3D printing enthusiasts.

There are of course a raft of other filament types that you might use but for the purposes of keeping this as simple as possible, I’ll just look at the following:

· PLA (Polylactic Acid)

· ABS (Acrylonitrile Butadiene Styrene)

· TPU (Thermoplastic Polyurethane) and

· PETG (Polyethylene Terephthalate Glycol)

There are variations of each of these produced by different manufacturers (Silk, Plus, glow in the dark for instance) but for now I’ll stick to the basic version of each type. The first thing to do is compare the average cost of a standard 2KG (2.2lbs) spool of each filament.

Table A: Average Filament Cost

|

Filament Type |

Roll Size |

Lowest Cost* |

Highest Cost* |

Average Cost |

|

PLA |

2KG (2.2lbs) |

$10 |

$20 |

$15 |

|

ABS |

2KG (2.2lbs) |

$15 |

$50 |

$32.50 |

|

TPU |

2KG (2.2lbs) |

$21 |

$33 |

$27 |

|

PETG |

2KG (2.2lbs) |

$14 |

$32 |

$23 |

(*Costs obtained from Amazon.com)

This isn’t a massively scientific table as there are some decent quality filaments out there that you can pick up cheaper than the lowest price and some that are much higher than the highest I’ve listed. This is also just from one supplier so costs and shipping charges etc. may vary between suppliers and countries. I think though that the average price of each filament gives a fair representation of the cost you might expect to pay.

Average filament usage

In one of my other articles, “Decoding the Mystery: How Much Filament Does a 3D Print Really Use?”, I looked at how much PLA it would take to make various different models. In the article, I chose ten Anime themed models that you can download for free from various sites and then sliced them in Cura using some standard settings. The resultant estimated filament usage was then produced and gave a pretty good idea of what to expect for these different styles and types of models.

Let’s now then use that data to look at roughly what each model would cost to print using the four types of filament I’ve listed above. To do that, here’s another table:

Table B: Filament cost per model

|

Model |

Filament Used* |

Filament Type and Cost |

|||

|

PLA |

ABS |

TPU |

PETG |

||

|

Anime

Girl |

175g |

$2.62 |

$5.69 |

$4.73 |

$4.03 |

|

Saitama

(One Punch Man) |

112g |

$1.68 |

$3.64 |

$2.80 |

$2.58 |

|

Pikachu

(Fanart) |

55g |

$0.82 |

$1.78 |

$1.38 |

$1.27 |

|

Monkey D.

Luffy (One Piece) |

254g |

$3.81 |

$8.26 |

$6.35 |

$5.84 |

|

Fat Yoshi |

279g |

$4.19 |

$9.07 |

$6.98 |

$6.42 |

|

Spy x

Family Loid Forger Lapel Pin |

1g |

$0.02 |

$0.03 |

$0.03 |

$0.02 |

|

Goku (Dragonball

Z) |

125g |

$1.88 |

$4.06 |

$3.13 |

$2.88 |

|

Shoto

Todoroki (My Hero Academia) |

110g |

$1.65 |

$3.58 |

$2.75 |

$2.53 |

|

Nezuko

(Dragon Slayer) |

133g |

$2.00 |

$4.32 |

$3.33 |

$3.06 |

|

Demon

Slayer- Hanafuda Keychain |

11g |

$0.17 |

$0.39 |

$0.28 |

$0.25 |

(*Filament usage is an estimate based on Cura sliced models)

So, you can see from Table B that if we use the average prices of filament from Table A and apply that to the estimated usage of the models sliced using Cura, you get an estimate of the material cost for printing each model. The one caveat to that is that using different materials may give you a slightly different estimate in Cura but the margins are +/- 5g on average. This will only change the overall estimated cost by around $0.08 for PLA and $0.16 for ABS as the two extremes of the cost range.

These figures also include the use of supports in some cases, a brim as the build plate adhesion setting and a 10% infill for the model and supports. You may find though that you use or prefer different settings to these. This of course will change things a bit in each case but that’s a variable I can’t calculate without using every setting combination.

On the subject of supports and build plate adhesion settings, these will all produce wastage that unfortunately is a cost that can’t be avoided. You can of course reduce the cost if you don’t use either but then you run the risk of your model failing and wasting all of that filament.

Another thing to bear in mind with the model examples I’ve given is that, as I mentioned earlier, all the files are free to download. Now, if you are a regular user of Thingiverse to find printable files and download them, then you’ll be aware that all the files on the site are indeed free. However, this isn’t the case with all file download sites out there.

Other sites where you can download other people’s designs include Cults 3D, My Mini Factory and CG Trader. These aren’t the only sites available but are probably the most used and popular. Granted there are some free files on each of these three sites but the majority will need to be paid for. This could run between around $1 up anything in the range $50+. These more expensive models will usually be of extremely high quality and design so they might be worth trying.

That should then give you an idea of filament costs and the potential cost of printable files, but unfortunately, that’s not where the ongoing 3D printing material cost ends. Let’s then take a look at some of the other consumables that you’ll need as well as some replacement parts for a few of the most popular printers on the market.

Ongoing 3D Printing Material Costs

I’ll admit that’s not the snappiest of titles for this section but it at least gives you an idea of what to expect.

3D printers are like pets, they don’t just need feeding regularly but also need care and attention to thrive. In this analogy, the food is the filament and the care and attention is regular maintenance and upkeep of your printer. The majority of FDM open frame, gantry style 3D printers are what’s termed as “open source”. This is a term that is usually applied to software which is developed by the original programmer but then can be adapted to suit the needs of the user. A good example of this in the 3D printing word is Cura which I’ve mentioned previously here and in other articles. Cura is a great program by itself and is probably used by the majority of people who own a 3D printer. However, other companies have taken the Cura base model and changed it in some ways to match with their printers. An example of this would be Creality who have used Cura to produce their own branded Creality Slicer and latterly, Creality Print. Have a look at Creality Slicer and its pretty much the same program as Cura but with a different name.

Open source 3D printers are similar in that they allow you to adapt and enhance the machine to suit your own needs. You can therefore replace virtually all of the parts if necessary and even print parts or adaptations for your printer. Mostly these enhancements would be by choice or personal preference so wouldn’t be considered essential maintenance. However, there are a few parts to a 3D printer that need changing on a regular basis.

I’ve chosen three of the most widely used makes and models of FDM printers out there and will show you what the rough cost of maintaining one of those machines might cost you. Let’s first then take a look at those and see what we’re dealing with.

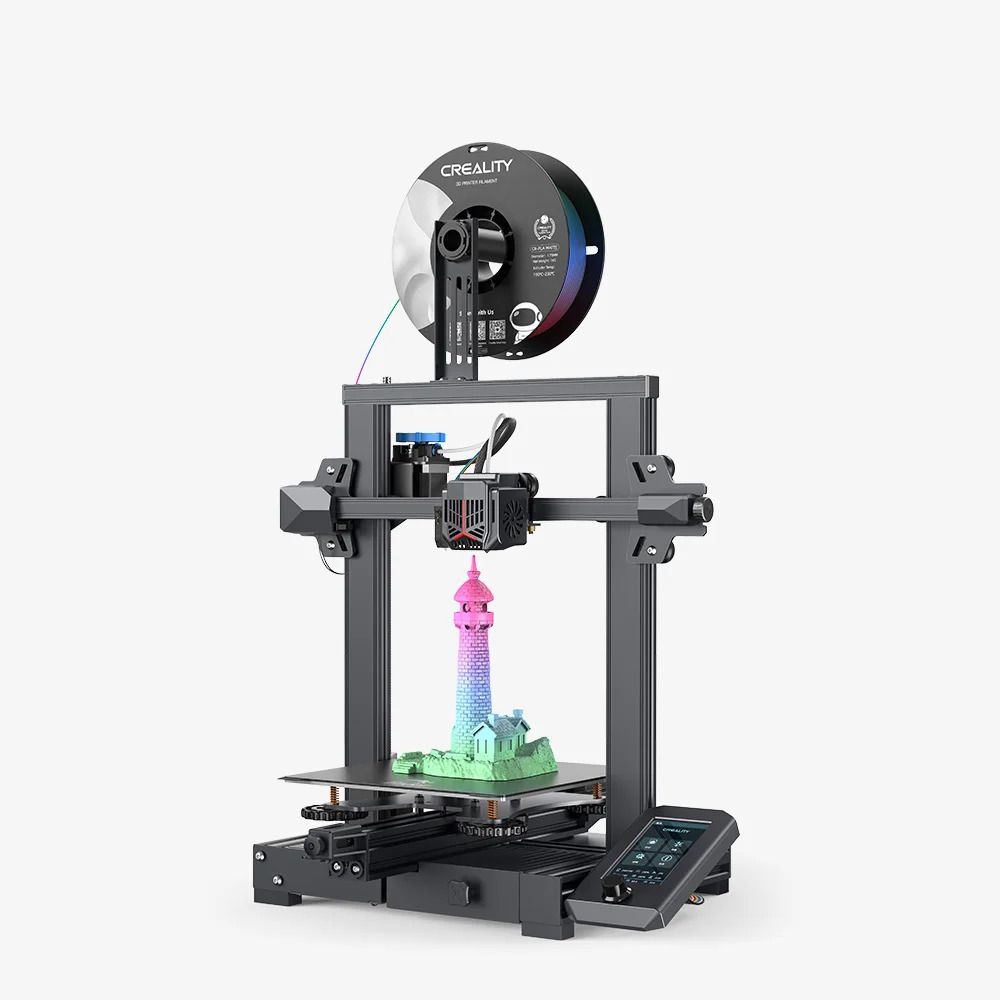

The Ender 3 range from Creality is probably the most popular and best selling of any FDM printer on the market. There have been many upgrades and incarnations of the Ender 3 over the past few years but probably the mid-range model in the stable is the Ender 3 V2 Neo. There may be additional features to the Neo than to the standard Ender 3 such as a better UI control pad, a better hot end and extruder, auto bed levelling and a magnetic flexible build plate but the consumable parts are pretty much the same.

Anycubic Kobra

Anycubic are another of the big hitters in the world of FDM open source 3D printers. The Kobra is again one of their most popular models and sits in the same price bracket at the Ender 3 V2 Neo. The features and design are also similar to the Ender but the Kobra has the advantage of a direct drive extruder as standard instead of a Bowden tube system as with the Ender. We’ll see later on why this may make a difference in costs. The overall build volume is slightly smaller than the Ender but in essence, you’re getting pretty much the same printer for your money.

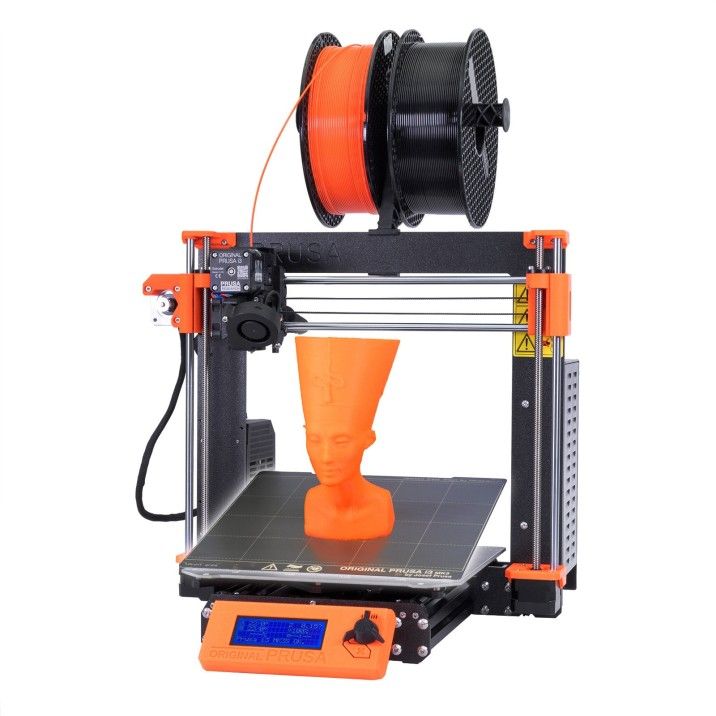

Original Prusa i3 MK3S+

Time to change things up a bit both in terms of price of the printer and the potential ongoing costs. Prusa have become very popular over the last few years by offering great printers as well as aftersales and customer support. The Original Prusa i3 MK3S+ is the latest in the Prusa range and is a bit more expensive than the other two (more than double really) but you do have the options of buying it fully built or as a kit which will save you around 30%. The advantages of the Prusa include a faster print speed and higher maximum nozzle temperature. The build volume is around the same as the Kobra but it’s the quality of the parts and the build that maker the extra cost worth consideration.

So, that’s our three printers decided upon but let’s now look firstly at the costs of regularly replaced consumable parts.

Replaceable Parts

Nozzles

The nozzle, although tiny, is the lifeblood of your 3D printer. If it becomes clogged or worn then the rest of the machine won’t matter as your printer simply won’t work.

Under regular use I’d advise changing the nozzle once a month but if it becomes damaged or another blockage problem occurs in the meantime, then change it anyway. The standard type of nozzle is made of brass as it’s a good conductor of heat and fairly cheap to produce. You can of course use nozzles made from steel or even titanium but we’re talking silly prices for those generally. Let’s for now then stick to good old reliable brass and compare the costs.

Table C: Nozzle cost comparison

|

Cost

per nozzle |

Cost

per print |

|

|

Creality Ender 3 V2 Neo |

$1.92 |

$0.06 |

|

Anycubic Kobra |

$3.80 |

$0.13 |

|

Original Prusa i3 MK3S+ |

$4.19 |

$0.14 |

Note that all these prices are if you buy direct from the manufacturer but you can buy cheaper, suitable versions elsewhere. Adding prices from the manufacturer though allows for a fairer comparison. Also, with Creality and Anycubic, the nozzles are sold in packs of five.

If we then use these figures and go by the rule of replacing one per month let’s say we get 30 days use out of it. You may well print more models in a day than most but an easy figure is one per day. So, divide the cost of the nozzle by 30 and you get an estimated cost per print which we can add later to the overall costs.

PTFE (Bowden) Tubing - Capricorn™

As mentioned above, this really only affects the Ender 3 V2 Neo as the other two have direct drive extruders. However, this tubing is something that also might need to be replaced and certainly will do if a blockage or damage occurs.

With the Ender, the standard white PTFE tubing isn’t really of any decent quality anyway so I’d always recommend changing it out as soon as you for a Capricorn™ branded tubing which you can again either buy direct from Creality or another online provider. These are usually sold in 1m lengths and you ideally need about 33cm for one printer so this will provide enough for three printers or three changes of tubing.

Table D: PTFE (Bowden) tubing – Capricorn™

|

Printer |

Cost per metre |

|

Creality

Ender 3 V2 Neo |

$11.00 |

|

Anycubic

Kobra |

N/A |

|

Original

Prusa i3 MK3S+ |

N/A |

It’s difficult to quantify how much tubing you’ll need to print one item as there isn’t a measurable lifespan for the tubing. Just bear in mind the cost if you do need to replace it though.

On that subject, there are a lot of parts to a 3D printer that can become worn or break, but we can’t determine how or when this will happen. As such, its such a variable figure that it would be virtually impossible to give an exact cost per print figure for each replaceable item.

However, its still worth comparing our three different printers in terms of replaceable parts so you can get an idea of how much each one might cost you to repair or maintain.

The build plate surface is something that will wear over time and use but if you look after it and don’t have any major mishaps then it should last a long time.

Each of our printers comes with a particular build plate surface as standard so let’s look at the cost of replacing them on a like for like basis.

Table E: Build plate surface

|

Printer |

Cost |

|

Creality

Ender 3 V2 Neo |

$30.00 |

|

Anycubic

Kobra |

$31.00 |

|

Original

Prusa i3 MK3S+ |

$38.00 |

Hot End/Extruder

The hot end or heated extruder setup is basically what does the pretty work after the design and theoretical side has been done. Again, this isn’t something that you should need to replace unless you have a minor disaster but you can of course decide to upgrade if you wanted.

In the case of the Ender, you’re getting everything including the housing, fans and wiring. The Kobra just gives you the hot end and wiring but then that should be all you need to replace. With the Prusa, you could purchase virtually every single individual part of the printer if you wanted so you can just buy the hot end and use the original housing.

Let’s again though look at the cost of a straight replacement.

Table F: Hot End/Extruder

|

Printer |

Cost |

|

Creality

Ender 3 V2 Neo |

$30.00 |

|

Anycubic

Kobra |

$25.00 |

|

Original

Prusa i3 MK3S+ |

$89.00 |

Driver/stepper Motors

The driver motors are what move the X, Y and Z axis of the printer and there’s also one for the extruder gear. Therefore four in total which are slightly different in size but cost is pretty much the same. You’ll often find full sets of four motors available to buy but it’s unlikely that all four will fail at once so you’re more likely to just want one.

Table G: Driver/stepper motors

|

Printer |

Cost per motor |

|

Creality

Ender 3 V2 Neo |

$12.00 |

|

Anycubic

Kobra |

$12.00 |

|

Original

Prusa i3 MK3S+ |

$42.00 |

Tensioning/timing belts

These are what the driver motors are connected to and provide movement of the X and Y axis. As with most parts of your printer they can become worn and/or loose so may need to be replaced at some point.

Table H: Tensioning/timing belts

|

Printer |

Cost per belt |

|

Creality

Ender 3 V2 Neo |

$6.00 |

|

Anycubic

Kobra |

$19.00 |

|

Original

Prusa i3 MK3S+ |

$6.00 |

UI/Control panel

The control panel is obviously vital to be able to get your printer working by adjusting settings and ultimately hitting “print”!

Breakdowns of this part are unlikely but do happen. Quite often it’s just a firmware issue that can be rectified with an update but if its something more serious then it will need replacing.

Just a note on pricing for this. Creality no longer sell the direct replacement board for the Ender 3 V2 Neo on their site so the price I’ve quoted is from Amazon.com. Anycubic simply don’t offer a replacement control panel anywhere it seems despite my searching. It looks likely then if the control panel fails your looking at a whole new printer.

Table I: UI/Control panel

|

Printer |

Cost |

|

Creality

Ender 3 V2 Neo |

$40.00 |

|

Anycubic

Kobra |

N/A |

|

Original

Prusa i3 MK3S+ |

$63.00 |

Mainboard

The mainboard is the brains of the whole operation and nothing works without it. As such, its something that should be treated with care, particularly when changing out another wired part such as the hot end or control panel.

The mainboards that come with our three chosen printers are pretty good and do everything you need them to do. If however you do decide to upgrade certain parts of your printer then you will probably at the very least need to update the firmware or you may even consider swapping it out for an upgrade.

If however disaster strikes and you just need to replace the one you’ve got then here are the costs.

Table J: Mainboard

|

Printer |

Cost |

|

Creality

Ender 3 V2 Neo |

$60.00 |

|

Anycubic

Kobra |

$65.00 |

|

$131.00 |

This guide is by no means comprehensive in terms of all the replacement or upgraded parts you could buy for your printer. The good thing is though that you are able to buy these parts and its not always a case of your printer breaking down and that’s it.

Right, for my final flourish, let’s see if we can work out the cost of printing our models that we looked at way back at the start of this piece.

As I said, working out the consumable cost of all the possible replacement parts in relation to printing cost would be impossible. However, we shouldn’t just dismiss those costs without some consideration. Therefore, there’s going to have to be a little bit of guess work and estimation going on to be able to work things out.

So, let’s give an estimated figure as to how long each part should/might last and see if we can transfer that into a cost per print. Stick with me as this might get complicated!

Table K: Estimated lifespan of most common replaceable parts

|

Replacement Part |

Estimated Lifespan (days) |

|

180 |

|

|

Build Plate Surface |

180 |

|

Hot End/Extruder |

720 |

|

Driver/stepper Motors |

1080 |

|

Tensioning/timing belts |

360 |

|

UI/Control panel |

1080 |

|

Mainboard |

1080 |

As I said, these are all very broad estimates and based mainly on my own experiences. Hopefully things like the motors and mainboard will last much longer but I have had to replace all of these things at least once on one of my printers in the time given.

The thing to do now though is to see if we can work out the daily cost of each part for each printer. Hold tight now, here comes another set of tables.

Table L: Creality Ender 3 V2 Neo

|

Replaceable Part |

Estimated Cost Per Day |

|

PTFE

(Bowden) Tubing - Capricorn™ |

$0.06 |

|

Build Plate

Surface |

$0.17 |

|

Hot

End/Extruder |

$0.04 |

|

Driver/stepper

Motors |

$0.01 |

|

Tensioning/timing

belts |

$0.02 |

|

UI/Control

panel |

$0.04 |

|

Mainboard |

$0.06 |

|

Total |

$0.40 |

Table M: Anycubic Kobra

|

Replaceable Part |

Estimated Cost Per Day |

|

PTFE

(Bowden) Tubing - Capricorn™ |

N/A |

|

Build Plate

Surface |

$0.17 |

|

Hot

End/Extruder |

$0.03 |

|

Driver/stepper

Motors |

$0.01 |

|

Tensioning/timing

belts |

$0.05 |

|

UI/Control

panel |

N/A |

|

Mainboard |

$0.06 |

|

Total |

$0.32 |

Table N: Original Prusa i3 MK3S+

|

Replaceable Part |

Estimated Cost Per Day |

|

PTFE

(Bowden) Tubing - Capricorn™ |

N/A |

|

Build Plate

Surface |

$0.21 |

|

Hot

End/Extruder |

$0.12 |

|

Driver/stepper

Motors |

$0.04 |

|

Tensioning/timing

belts |

$0.02 |

|

UI/Control

panel |

$0.06 |

|

Mainboard |

$0.12 |

|

Total |

$0.57 |

These might not seem like massive figures but when you apply them all together with the other costs I’ve looked at then it starts to stack up.

We’re getting close to the end now (collective “phews” all round) so the final thing to do is to calculate the average cost of a 3D print based on the figures that have been gathered so far.

Rather than give a figure for each of the models that we looked at in Table A, let’s take an average of those costs and apply them just to the different types of filament. I’ll disregard the two lowest cost items as this will skew the average so the other eight will be used instead.

Table AA: Average cost of filament for a 3D printed model

|

Type of Filament |

Average Cost per Model |

|

PLA |

$2.33 |

|

ABS |

$5.05 |

|

TPU |

$3.93 |

|

PETG |

£3.58 |

The Final Count

OK, so now we have a good starting figure for our final calculation to see what 3d printing materials cost. What we need to do now though is to add the other figures from Table C and calculate our costs based on the three different printers and the four filament types. These will be the figures shown in Table AA and tables L-N.

Table BB: Average cost of a 3D print by printer and filament type

|

Printer |

Average cost by Filament Type |

|||

|

PLA |

ABS |

TPU |

PETG |

|

|

Creality

Ender 3 V2 Neo |

$2.79 |

$5.51 |

$4.42 |

$4.04 |

|

Anycubic

Kobra |

$2.28 |

$5.50 |

$4,38 |

$4.03 |

|

Original

Prusa i3 MK3S+ |

$3.04 |

$5.76 |

$4.64 |

$4.29 |

|

Final Average |

$2.70 |

$5.59 |

$4,48 |

$4.12 |

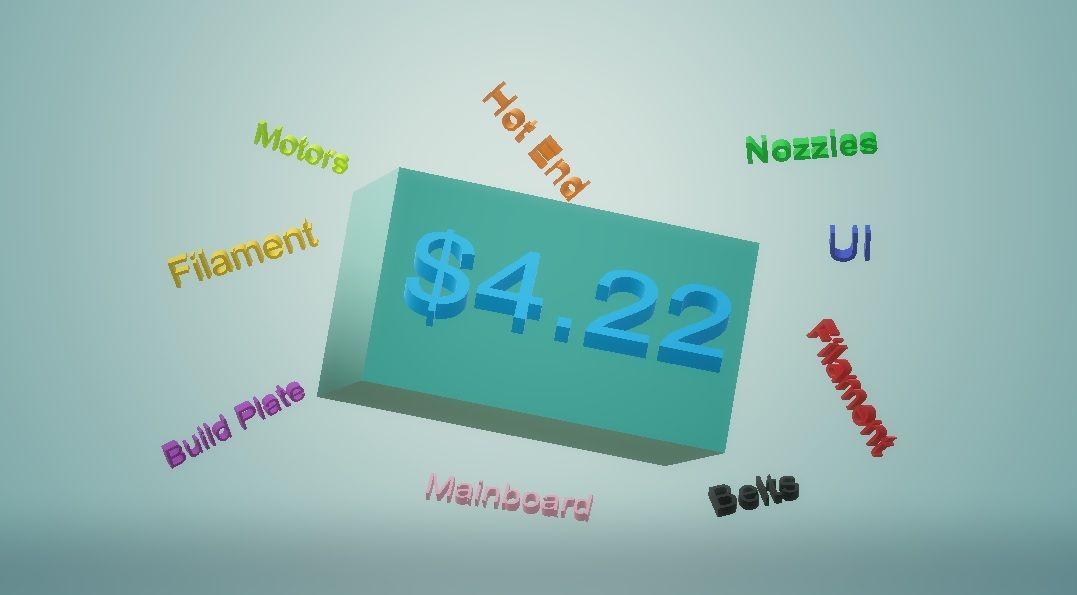

Finally, the average cost of printing a 3D model using my totally non-scientific but still mathematically sound method is…..

As I’ve said, this isn’t a totally infallible way of working out the total cost of a print and it doesn’t consider the variables that I’ve mentioned before. Other variables that might affect this slightly are energy costs both for the printer and the room you’re using, any glue or other adhesive material you might use to help with bed adhesion and anything else that you can think of that might add cost.

I think though that you’ll at least get something out of my attempt at calculating how much 3D printing materials cost and it might give you an idea of what you’re letting yourself in for when you enter the wonderful world that is, 3D printing!

Member discussion